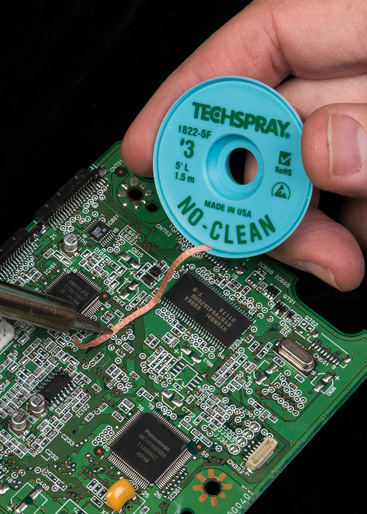

Techspray는 귀하의 공정과 제품개발 개선을 위해 최선의 화학 제품을 제공합니다

우리는 전자 제품의 신뢰성과 수명을 개선하고 전체 생산을 최적화하기 위해 효과적이고 고품질의 세척제, 컨포멀 코팅 및 기타 화학 제품을 설계합니다.

Press Release

항공기에서 가장 오염이 심한 부위중 하나는 전혀 놀랍지 않게도 엔진입니다. 엔진은 항공기의 도래 이후로 많은 발전이 있었지만 여전히 많은 양의 탄소를 배출합니다. 물론 탄소는 부식의 주요 원인입니다. 하지만 엔진의 경우 부식은 더 많은 문제들을 야기할 수 있습니다. 현대의 엔진 덮개는 단순히 엔진을 씌우는 것을 넘어서 더 많은 기능을 하는 놀라운 디자인입니다; 이는 엔진으로부터 공기의 흐름이 제대로 되도록 공기역학적으로 디자인되었으며 엔진의 부수적인 구동 시스템을 보호합니다. 놀랍지 않게도, 엔진 덮개는 민감한 곳임과 동시에 더러운 곳입니다.

다음...